In pathology, biology, forensic science, materials science, and various engineering and applied science fields, the grossing station (also known as a grossing table, dissection table, or specimen processing workstation) is an indispensable piece of infrastructure. It is far more than a simple work surface—it is a professional workstation that integrates engineering design, ergonomics, safety protection, and environmental control. Its core purpose is to provide a safe, clean, efficient, and ergonomically optimized platform for handling specimens, serving as the first line of defense for operator safety, specimen integrity, and the accuracy of subsequent experimental results.

I. Core Functions and Applications

The design of a grossing station revolves around its core mission and can be divided into several major functions:

1. Primary Operating Platform

a. Macroscopic specimen handling:

This is the most direct function of the grossing station. Engineers, pathologists, or researchers use it to cut, measure, describe, and select target areas from biological tissues, organs, industrial materials, or forensic samples. A sturdy, corrosion-resistant, and perfectly flat surface provides the foundation for precise operations.

2. Operator Safety Protection (Core of Engineering Safety)

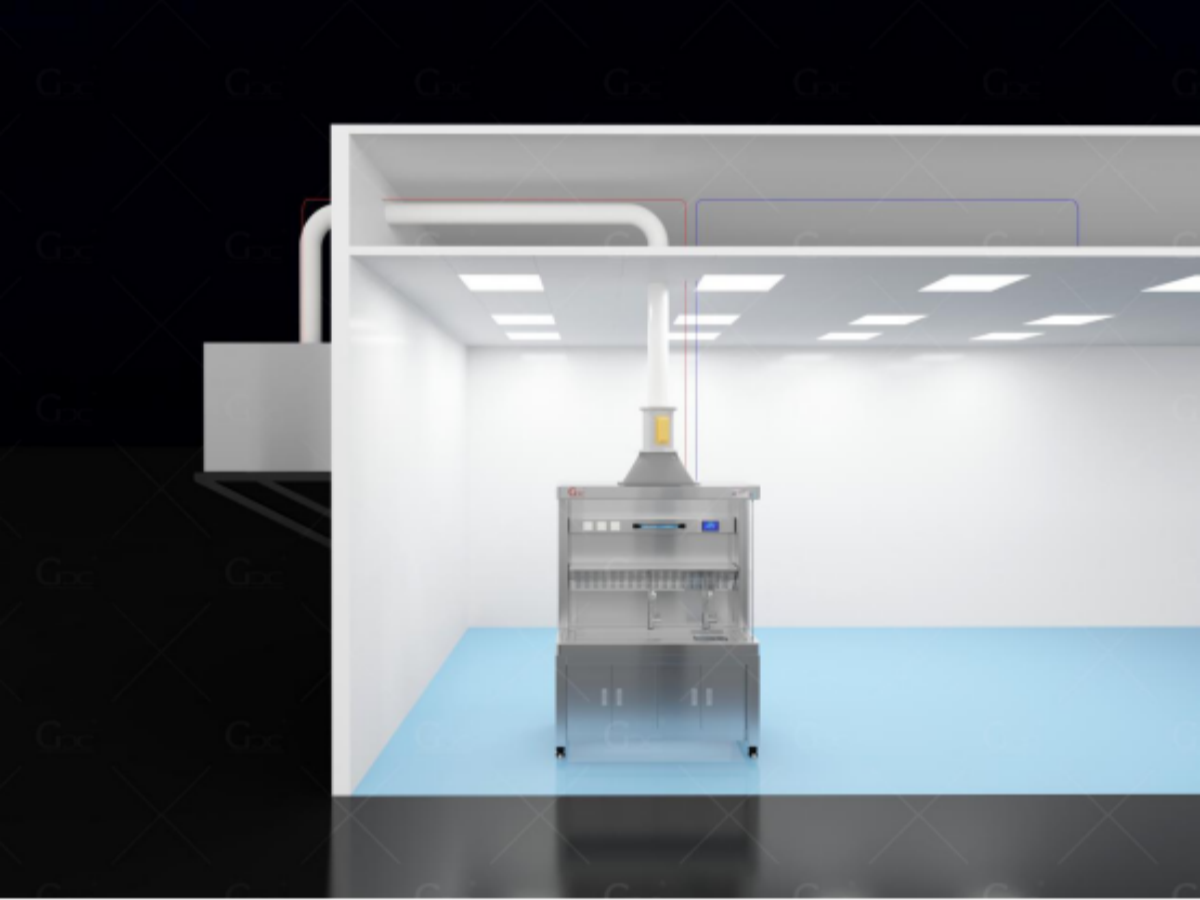

a. Exhaust and fume extraction system:

When handling tissue specimens—especially those fixed with formalin—harmful volatile gases such as formaldehyde can be released. The grossing station’s integrated negative-pressure exhaust system creates a stable airflow barrier in front of the operator’s breathing zone, instantly capturing harmful gases and aerosols and discharging them through high-efficiency filtration. This dramatically reduces occupational exposure risks and is one of its most critical engineering safety features.

b. Physical barriers:

Splash guards and transparent shields help prevent liquid droplets or solid fragments produced during cutting or manipulation from splashing, protecting the operator from biological or chemical contamination.

3. Specimen Environmental Protection

a. Cross-contamination prevention:

The stainless steel, seamless, corrosion-resistant, and easy-to-sanitize surface ensures that different specimens do not contaminate each other. It supports thorough cleaning and disinfection after each use to meet strict laboratory cleanliness requirements.

b. Maintaining specimen integrity:

Built-in cooling systems (such as chilled tabletops) can reduce temperature during handling, slowing down autolysis or degradation and providing ideal conditions for temperature-sensitive specimens.

4. Ergonomic Optimization

a. Comfort and efficiency:

Modern grossing stations often feature adjustable height systems, allowing operators of different statures to work comfortably for extended periods, reducing musculoskeletal strain. Thoughtful layout of sinks, tool racks, and integrated lighting streamlines workflow and enhances efficiency.

b. Integrated lighting:

Shadow-free, cool-light illumination provides bright and glare-free visibility, ensuring precise handling and accurate recognition of structural details.

5. Wastewater and Waste Management

a. Waste liquid collection:

Sloped channels and drainage systems direct waste liquids into designated collection units for centralized and environmentally compliant treatment.

b. Solid waste segregation:

Multiple waste bins are typically included to separate sharps, biohazardous waste, and non-hazardous waste, ensuring proper laboratory waste management.

II. Engineering Design Characteristics

The applications of a grossing station directly determine its engineering design features:

- Materials:

Usually constructed from 304 or 316 stainless steel for outstanding corrosion resistance, mechanical strength, easy cleaning, and antimicrobial properties. - Structure:

A stable, robust structure capable of bearing heavy loads and resisting vibration during operation. Modular designs allow flexible configuration of sinks, drying racks, storage cabinets, and other components. - Ventilation System:

The core includes fans, dampers, and ducting. Requirements include stable face velocity (typically 0.3–0.5 m/s), low noise, low energy consumption, and filtration performance that meets relevant safety standards.

III. Application Scenarios

Grossing stations are widely used across medical and non-medical fields:

- Medical:

Hospital pathology departments, forensic units, biobanks. - Life Science Research:

University labs, animal research facilities, biological research institutions. - Industrial:

Food processing (meat inspection, quality analysis), pharmaceutical manufacturing (raw material inspection). - Forensic & Engineering:

Material failure analysis, evidence handling in accident investigations.

IV. Selection Considerations

Selecting the right grossing station requires a systematic assessment:

- Specimen type:

Whether handling hazardous chemicals or biological risks. - Space layout:

Compatibility with the laboratory’s ventilation system and workflow. - Regulatory compliance:

Alignment with national biosafety and occupational health standards. - Ergonomic needs:

Height adjustment range, lighting quality, noise level, etc.

Conclusion

A grossing station is a highly specialized engineering product. Its functions extend far beyond that of a simple table; it is a comprehensive solution integrating safety protection, contamination control, workflow optimization, and ergonomic design. Its value lies in safeguarding people, preserving specimen quality, and enhancing operational efficiency. Investing in a well-designed, fully functional grossing station is an essential commitment to operator health, environmental safety, and the reliability of scientific data.

坤灵最新logo-scaled-1.png)