Microtome in Pathology: Technical Guide for Histological Sectioning | Principles & Uses

Explore the role of microtomes in pathology labs. Learn how these precision instruments produce thin tissue sections for accurate diagnosis and research.

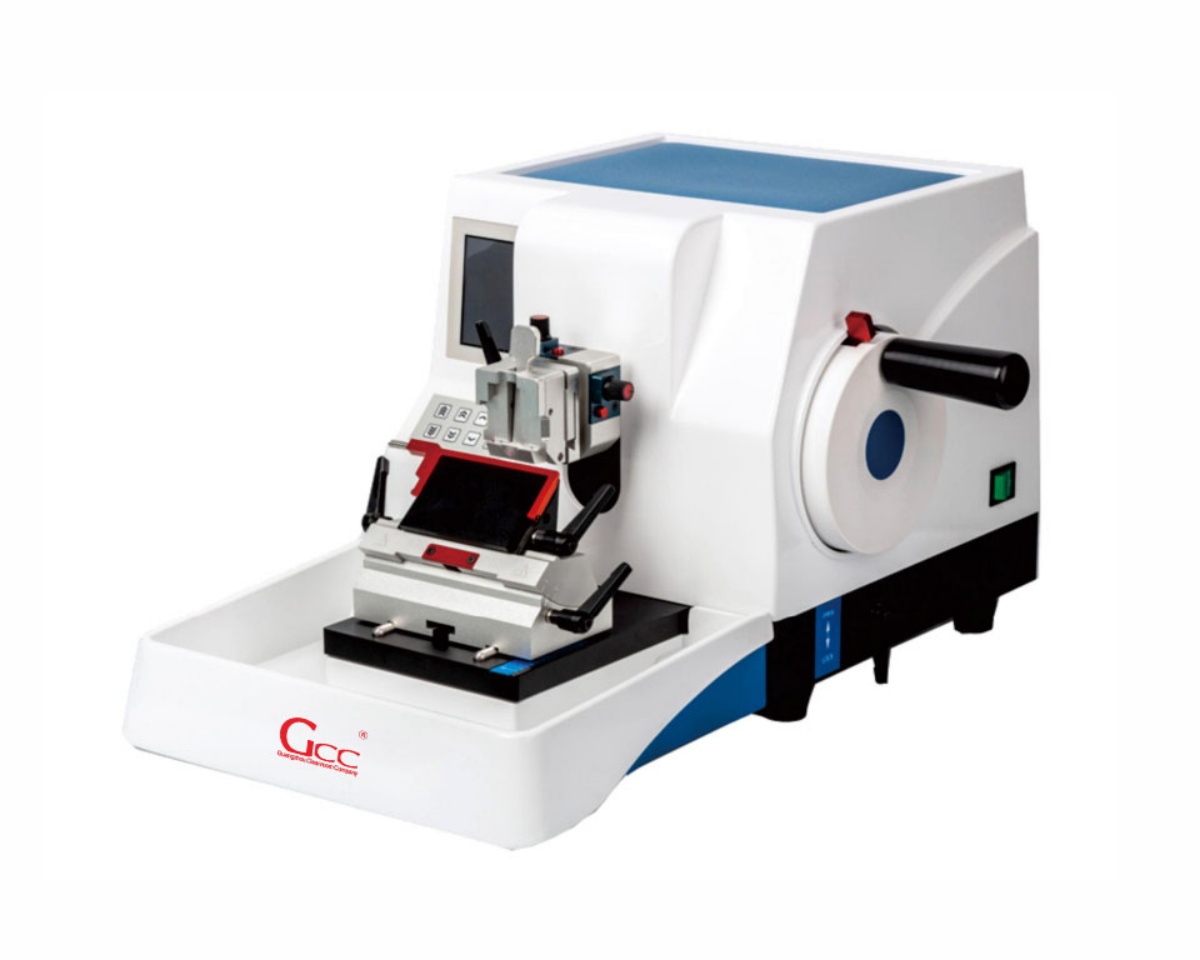

Microtome in Pathology: A Comprehensive Technical Overview

Precision Instrumentation for Histological Sectioning

A microtome (from the Greek words mikros, meaning “small,” and temnein, meaning “to cut”) is an essential precision instrument used in histology and pathology laboratories to produce extremely thin sections of biological specimens, typically ranging from 2 to 10 micrometers (µm) in thickness.

These thin sections are mounted on glass slides, stained, and examined under a microscope to aid in diagnostic processes. In fact, the microtome is an indispensable tool in anatomical pathology, enabling detailed morphological analysis of tissues critical for disease diagnosis, research, and education.

I. Definition and Overview

Microtomes play a foundational role in modern pathology. By allowing technicians to cut uniformly thin tissue sections, these instruments ensure that samples are properly prepared for microscopic evaluation. Whether for diagnostic, research, or training purposes, microtomes help reveal cellular structures and abnormalities that inform medical decisions.

II. Working Principle

The fundamental operating principle of a microtome involves the precise mechanical advancement of a tissue block against an extremely sharp blade. Most modern microtomes include a retraction mechanism that lifts the tissue block during the return stroke. This prevents damage to the specimen and ensures the integrity of each section.

Key steps in the cutting process include:

- Secure clamping of the paraffin-embedded or frozen tissue block

- Precise adjustment of section thickness using a calibrated advancement mechanism

- Manual or automated cutting motion with the blade set at a specific clearance angle

- Collection of the resulting ribbon of serial sections for further processing

A smooth and consistent cutting action is critical to producing sections of uniform thickness. Artifacts like compression or chatter can compromise diagnostic accuracy.

III. Primary Functions and Roles

Microtomes serve multiple essential functions in pathology laboratories, such as:

- Sectioning: Producing thin, uniform tissue sections for microscopic examination.

- Serial Sectioning: Generating consecutive sections for 3D reconstruction or multiple staining protocols.

- Specialized Preparation: Creating sections for techniques like immunohistochemistry, in situ hybridization, and other specialized stains.

- Research Applications: Preparing high-quality specimens for experimental pathology and academic research.

The quality of microtome sections directly affects diagnostic accuracy, underscoring the importance of this instrument in patient care.

IV. Structural Characteristics and Materials

Modern microtomes are engineered for precision, durability, and reliability. Common structural features include:

- Base and Frame: Heavy, vibration-resistant cast iron or steel to ensure cutting stability.

- Specimen Holder: A precision chuck or clamp mechanism to secure tissue cassettes firmly.

- Knife Holder: A reliable mounting system for disposable or permanent blades.

- Advancement Mechanism: A micrometer system for accurate thickness control, often with both coarse and fine adjustments.

- Handwheel: Ergonomically designed for smooth operation and control.

- Materials: Corrosion-resistant coatings, stainless steel, and hardened alloys ensure longevity even in demanding lab environments.

V. Classification and Technical Parameters

Microtomes are classified based on their mechanism of action and applications:

| Type | Mechanism | Typical Thickness | Primary Applications |

|---|---|---|---|

| Rotary Microtome | Rotating handwheel moves specimen past blade | 1–60 µm | Routine paraffin sectioning, high-volume labs |

| Cryostat Microtome | Motorized cutting in refrigerated chamber | 5–20 µm | Frozen sections, intraoperative consultations |

| Sliding Microtome | Blade moves horizontally past specimen | 3–40 µm | Large or hard blocks, celloidin-embedded specimens |

| Ultramicrotome | Thermal/mechanical advancement; diamond knife | 60–100 nm | Electron microscopy specimens |

VI. Typical Application Scenarios

Microtomes are used across various settings, including:

- Anatomic Pathology Labs: For routine diagnostic histology processing.

- Intraoperative Consultations: Using cryostat microtomes for frozen section analysis during surgery.

- Research Institutions: Preparing specimens for experimental studies.

- Forensic Pathology: Supporting tissue examination in medicolegal cases.

- Academic Medical Centers: Training pathology residents and medical students in histological techniques.

VII. Installation and Usage Considerations

Proper installation and operation are crucial for optimal microtome performance. Consider the following:

- Install the instrument on a stable, vibration-free surface.

- Maintain appropriate temperature and humidity levels.

- Ensure compliance with electrical safety standards and proper grounding.

- Follow the manufacturer’s guidelines for assembly, calibration, and operation.

- Implement safety protocols for blade handling and use personal protective equipment (PPE).

- Adhere to laboratory safety standards, including OSHA guidelines for sharps handling.

Note on International Standards:

Regulated environments should comply with standards such as ISO 9001 (Quality Management), ISO 13485 (Medical Devices), and ISO 14644 (Cleanrooms). Proper documentation of installation, calibration, and maintenance is essential for accredited laboratories.

VIII. Maintenance and Preservation Recommendations

Regular maintenance ensures consistent performance and extends the instrument’s lifespan:

- Daily Cleaning: Remove paraffin and tissue debris using soft brushes and solvents.

- Blade Replacement: Change disposable blades regularly; sharpen permanent knives as needed.

- Lubrication: Apply lubricants to moving parts per the manufacturer’s schedule.

- Calibration Verification: Regularly check section thickness accuracy with precision micrometers.

- Corrosion Prevention: Wipe metal surfaces with anti-corrosion solutions.

- Professional Servicing: Schedule annual maintenance and calibration by certified technicians.

- Disinfection: Follow lab biosafety guidelines for decontamination.

Maintain detailed records of all maintenance activities as part of your quality assurance program.

Conclusion

Microtomes are vital to the field of pathology, providing the precision and reliability needed for accurate tissue sectioning. From diagnostic applications to research and training, these instruments help uncover critical insights into disease mechanisms. Proper use, regular maintenance, and adherence to safety and international standards ensure that microtomes continue to support high-quality patient care and scientific advancement.