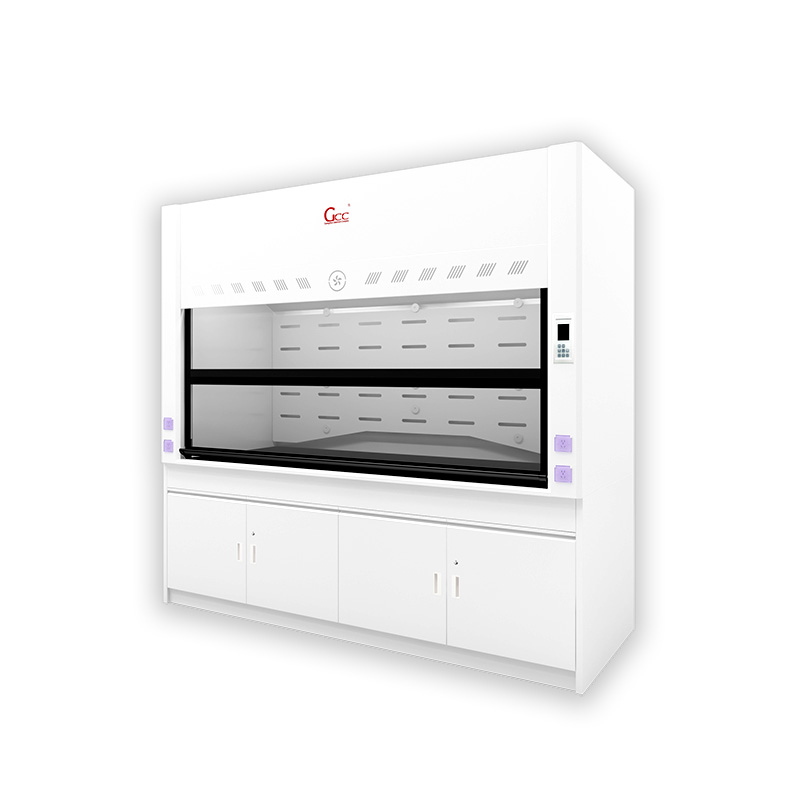

The Stain & Coverslip Integrated Fume Hood is engineered to streamline pathology staining and coverslipping workflows while ensuring maximum operator safety. By combining high-efficiency dual-channel exhaust, precise negative-pressure control, and optimized airflow design, this system rapidly removes xylene, formalin, and other harmful vapors. As a result, laboratories can significantly reduce chemical exposure risks, improve staining quality, and achieve higher operational efficiency. Moreover, its integrated design enhances process continuity, making it an essential solution for modern pathology labs seeking standardization and advanced safety performance.

Key Features:

-

Integrated Workflow Design

Combines staining and coverslipping in one enclosed, ventilated system to reduce contamination risks and improve operational efficiency. -

Advanced Negative Pressure Control

Continuously maintains −50Pa to −80Pa negative pressure, while automatically adjusting airflow to ensure rapid extraction of xylene and formalin vapors. -

Optimized Dual-Channel Exhaust System

Internal airflow guide plates prevent turbulence above staining tanks, ensuring uniform chemical vapor removal and stable staining quality. -

High Safety Protection

Ensures ≥1.0 m/s face velocity during staining and ≥0.8 m/s during coverslipping, effectively isolating hazardous fumes. -

Ergonomic and Durable Structure

Features a clear glass sash, corrosion-resistant working surface, and intuitive control panel to support long-term, stable operation.

Technical Specifications:

-

External Dimensions: 2500×1100×2350 mm

-

Internal Dimensions: 2200×1000×1050 mm

-

Working Face Velocity: 0.3–0.8 m/s

-

Exhaust Volume (0.5 m/s, full-open sash): ≈ 3500 m³/h

-

Sash Opening Height: 650–700 mm

-

Lighting: 30W daylight lamp

坤灵最新logo-scaled-1.png)

Reviews

There are no reviews yet.