This comprehensive guide explores the essential role of microtomes in pathology laboratories. We examine how these precision instruments work, their critical functions in diagnostic processes, technical specifications, and proper maintenance protocols. Additionally, we discuss how modern microtomes comply with international standards like GMP and ISO 14644.

I. Definition and Overview of Microtomes

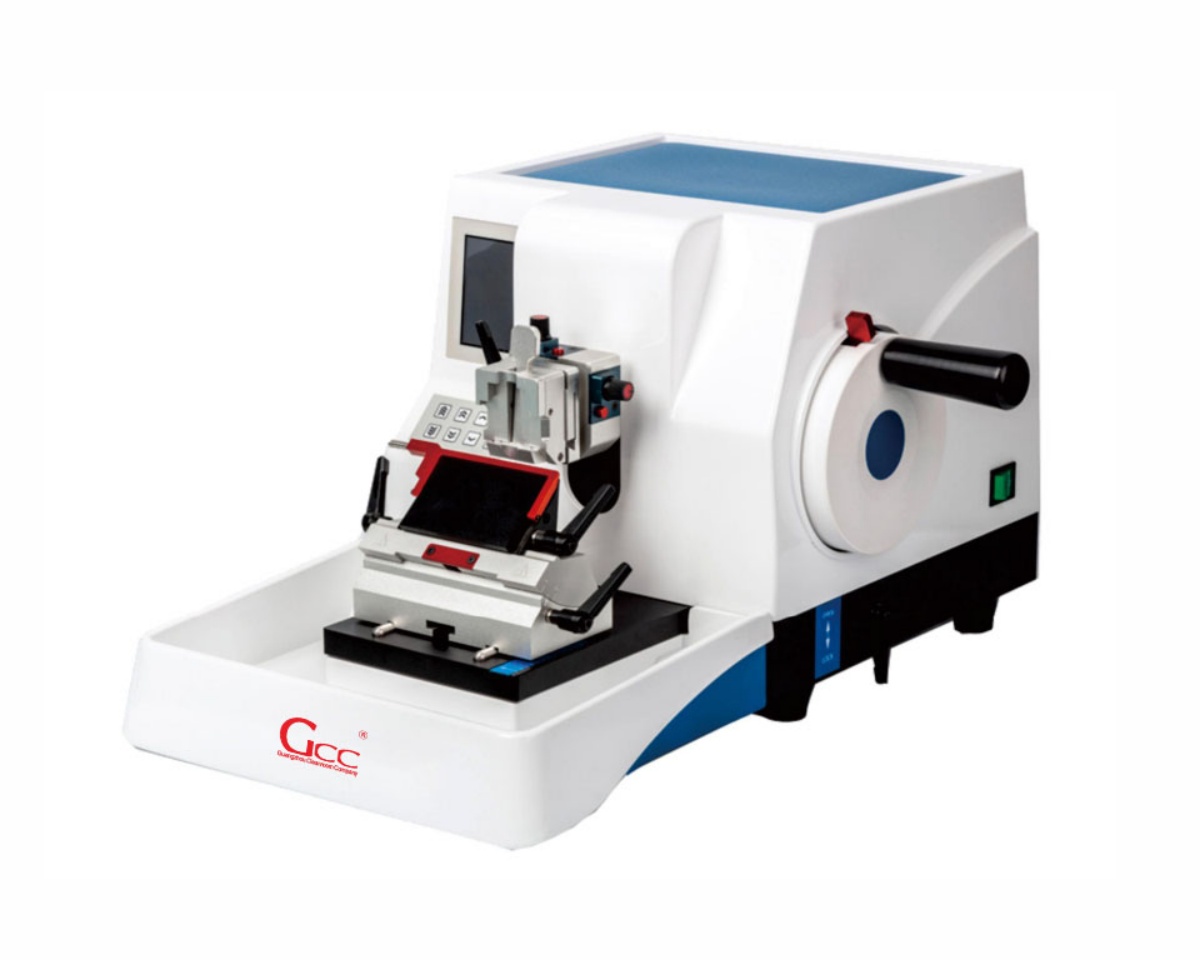

A microtome serves as a precision cutting instrument in pathology and histology laboratories, specifically designed to produce extremely thin sections of biological specimens for microscopic examination. These devices enable technicians to prepare tissue samples with consistent thickness, which proves absolutely crucial for accurate diagnosis and research.

Let’s now examine the key terminology professionals use when discussing microtomes:

Key Terminology:

- Microtome: Instrument for cutting thin sections of tissue for microscopic study

- Sectioning: Process of cutting tissue into thin slices

- Paraffin embedding: Technique of infiltrating tissue with paraffin wax to provide support during sectioning

- Cryosectioning: Cutting frozen tissue samples without embedding medium

- Ribbon: Series of consecutive tissue sections that adhere together during cutting

II. Working Principle of Microtomes

The microtome operates on the principle of precise mechanical advancement of a tissue block toward a cutting blade. This fundamental mechanism involves several coordinated actions that together produce high-quality tissue sections.

Specifically, the sectioning process includes these essential components:

- Sample Advancement: A precision feed mechanism advances the tissue block in micrometer increments (typically 1-50 μm) toward the cutting blade

- Cutting Action: A sharp blade moves across the tissue block in either a rotary, sliding, or rocking motion to produce thin sections

- Section Collection: Technicians carefully transfer the resulting tissue sections to glass slides for staining and microscopic examination

- Temperature Control: In cryostat microtomes, temperature regulation (typically -15°C to -30°C) maintains tissue integrity during sectioning

III. Primary Functions and Roles in Pathology

Microtomes serve several critical functions in pathological diagnosis and research. These instruments form the foundation of tissue-based diagnostics in modern medicine.

Specifically, pathology laboratories rely on microtomes for these essential tasks:

- Diagnostic Tissue Preparation: Production of thin tissue sections for light microscopy analysis

- Special Staining Procedures: Preparation of sections for immunohistochemistry (IHC), in situ hybridization, and special stains

- Intraoperative Consultation: Rapid frozen section analysis during surgical procedures

- Research Applications: Creation of serial sections for three-dimensional reconstruction studies

- Archival Material: Sectioning of paraffin-embedded tissue blocks for biobanking and retrospective studies

IV. Structural Features and Materials

Modern microtomes incorporate sophisticated engineering and premium materials to ensure precision and durability. Manufacturers design these instruments to withstand years of daily use in busy laboratory environments.

Specifically, high-quality microtomes feature these important structural elements:

- Frame Construction: Heavy-duty cast iron or aluminum alloy base for vibration dampening and stability

- Cutting Mechanism: Precision-ground gears and lead screws for accurate section thickness control

- Blade Assembly: High-grade steel disposable blades or reusable knives with adjustable angle settings

- Specimen Holders: Adjustable clamping systems compatible with various embedding cassettes

- Safety Features: Blade guards, automatic retraction systems, and safety locks

- Ergonomic Design: Adjustable handwheels, anti-fatigue matting, and accessible controls

V. Classification and Technical Parameters

Laboratories select microtomes based on their cutting mechanism and specific application requirements. Understanding these classifications helps pathology departments choose the most appropriate equipment for their diagnostic needs.

The following table compares the main microtome types and their technical specifications:

| Type | Section Thickness Range (μm) | Typical Applications | Power Requirements | Dimensions (W×D×H cm) | Weight (kg) |

|---|---|---|---|---|---|

| Rotary Microtome | 1-60 | Routine paraffin sections | Manual / 50W motorized | 40×35×45 | 25-40 |

| Cryostat Microtome | 5-50 | Frozen sections, IHC | 500-800W (including refrigeration) | 80×70×150 | 150-250 |

| Sliding Microtome | 1-100 | Large or hard tissue blocks | Manual / 100W motorized | 45×40×35 | 30-50 |

| Ultramicrotome | 0.05-1 | Electron microscopy | 100-150W | 50×45×40 | 50-70 |

| Laser Microtome | 5-100 | Contact-free sectioning | 2000-3000W (laser system) | 100×80×180 | 300-400 |

VI. Typical Application Industries

Microtomes have become indispensable instruments in various healthcare and research settings. Their precision sectioning capabilities support numerous diagnostic and research activities across multiple sectors.

Specifically, these industries rely heavily on microtome technology:

- Hospital Pathology Departments: Routine diagnostic histopathology, frozen section services

- Academic Research Institutions: Basic science research, tissue banking, morphological studies

- Pharmaceutical Industry: Drug development, toxicopathology, preclinical studies

- Veterinary Diagnostics: Animal tissue analysis, veterinary pathology

- Forensic Laboratories: Post-mortem examinations, forensic pathology

- Biotechnology Companies: Biomarker development, diagnostic test validation

VII. Installation and Usage Considerations

Proper installation and operation prove critical for optimal performance and compliance with international standards. Laboratories must follow specific protocols to ensure their microtomes function reliably and produce consistent results.

Specifically, pathology departments should address these important considerations:

- Site Requirements: Stable, vibration-free surface; adequate clearance for operation and maintenance

- Environmental Controls: Temperature stability (18-22°C), humidity control (40-60% RH)

- Electrical Requirements: Stable power supply with appropriate grounding; surge protection

- Safety Compliance: Adherence to IEC 61010 safety standards for laboratory equipment

- Cleanroom Standards: For cryostat installations, compliance with ISO 14644 cleanroom classifications

- GMP Considerations: Documentation of installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ)

- User Training: Comprehensive training on proper operation, safety protocols, and basic troubleshooting

VIII. Maintenance and Servicing Recommendations

A structured maintenance program ensures consistent performance and extends instrument lifespan. Regular maintenance prevents unexpected downtime and maintains section quality for accurate diagnoses.

The following table outlines a comprehensive maintenance schedule for pathology laboratories:

| Maintenance Activity | Frequency | Procedure | Documentation Required |

|---|---|---|---|

| Routine Cleaning | Daily / After each use | Remove debris, clean with 70% ethanol, lubricate moving parts | Cleaning log |

| Blade Replacement | As needed / Weekly | Replace disposable blades; sharpen permanent knives | Blade usage log |

| Performance Verification | Monthly | Check section thickness accuracy, feed mechanism consistency | Calibration certificate |

| Comprehensive Service | Every 6 months | Complete inspection, lubrication, adjustment of all components | Service report |

| Filter Replacement (Cryostats) | Every 3-6 months | Replace HEPA filters, clean condenser coils | Filter change record |

| Full Calibration | Annually | Complete calibration by certified technician | Calibration certificate |

Critical Maintenance Considerations:

- Use only manufacturer-recommended cleaning agents and lubricants

- Maintain detailed service records for quality assurance and regulatory compliance

- Schedule preventive maintenance during periods of low laboratory activity

- Train multiple operators to ensure consistent handling and care

- Implement a system for reporting and addressing performance issues promptly

Conclusion

Microtomes represent fundamental instruments in modern pathology, enabling precise tissue sectioning for diagnostic and research purposes. Understanding their working principles, applications, and maintenance requirements ensures optimal performance and reliable results. By implementing proper operating procedures and maintenance schedules, pathology laboratories can maximize their investment in these essential tools while maintaining compliance with international standards.

Enhance Your Pathology Laboratory with Trusted Equipment & Solutions

GCC Pathology delivers advanced pathology instruments, integrated solutions, and expert support tailored to your lab’s needs.

Ensure precision, safety, and efficiency with our world-class products and services.

Contact Us Today to discuss your project.

坤灵最新logo-scaled-1.png)