With the rapid development of the healthcare industry, pathology has become increasingly critical in clinical diagnosis. As a core component of medical diagnostics, pathology laboratories must not only follow strict operational standards but also integrate effective ventilation systems and exhaust gas treatment technologies during design and construction. Proper ventilation and exhaust systems ensure laboratory safety, maintain environmental compliance, and protect personnel health.

This article provides a detailed analysis of pathology laboratory ventilation systems and exhaust gas treatment technologies, helping engineers and laboratory planners implement efficient, safe, and compliant solutions.

1. Design Requirements for Pathology Laboratory Ventilation Systems

Pathology laboratories often handle hazardous materials, including chemical reagents, pathogens, and toxic fumes, during tissue processing, staining, and microscopic analysis. Therefore, designing and implementing a reliable ventilation system is critical. It not only protects laboratory personnel but also ensures a safe and compliant working environment.

1.1 Air Exchange Requirements

According to national pathology laboratory construction and management standards, laboratories must maintain good air circulation, typically requiring 6–10 air changes per hour. In addition, laboratory benches and areas with strong odors should have enhanced local exhaust ventilation to maintain air freshness and cleanliness.

1.2 Local Exhaust Systems

Certain laboratory zones, such as microscope workstations and tissue processing tables, require local exhaust systems to remove harmful gases and chemical vapors effectively. These systems often combine HEPA filtration and activated carbon adsorption to purify the air. Especially when handling formaldehyde, xylene, alcohol, or other volatile chemicals, local exhaust systems prevent hazardous gases from spreading to other areas.

1.3 Airflow Direction Design

Laboratory airflow should move from clean areas toward contaminated areas, preventing pollutants from spreading. Designing airflow direction carefully minimizes harmful gas exposure for personnel and reduces cross-contamination.

1.4 Automated Control Systems

Modern pathology laboratories integrate automated ventilation control systems to monitor indoor air quality and ventilation rates in real time. These systems adjust air exchange based on pollutant concentration, improving energy efficiency and reducing operational costs.

2. Exhaust Gas Treatment Technologies

Pathology laboratories generate exhaust gases containing organic solvent vapors, chemical reagents, bacteria, viruses, and other pollutants. Improper handling of these gases can threaten personnel health and harm the environment. Therefore, designing and selecting appropriate exhaust gas treatment systems is essential.

2.1 Formaldehyde Exhaust Treatment

Formaldehyde is commonly used for specimen fixation and is highly toxic with a pungent odor. Effective treatment methods include:

- Activated Carbon Adsorption: Adsorbs formaldehyde and other harmful gases efficiently.

- Photocatalytic Oxidation: Uses photocatalysis to decompose formaldehyde and other organic pollutants, offering a green and environmentally friendly solution.

2.2 Xylene Exhaust Treatment

Xylene, used for tissue dehydration and clearing, is highly volatile and toxic. Treatment methods include:

- Activated Carbon Adsorption: Effectively removes xylene vapors.

- UV Photolysis: Uses ultraviolet light to break down xylene molecules, reducing toxic emissions.

2.3 Alcohol Exhaust Treatment

Alcohol is widely used for sterilization and cleaning, but its high volatility can cause air pollution. Treatment methods include:

- Activated Carbon Adsorption: Prevents alcohol fumes from spreading.

- Chemical Absorption Towers: Removes harmful alcohol components through chemical reactions.

2.4 Exhaust Gas Purification Technologies

Different exhaust gases require specific treatment solutions:

- Activated Carbon Filters: Remove volatile organic compounds (VOCs) and malodorous gases.

- UV Photolysis Units: Decompose organic pollutants in exhaust gases.

- Chemical Absorption Towers: Neutralize highly toxic or corrosive gases.

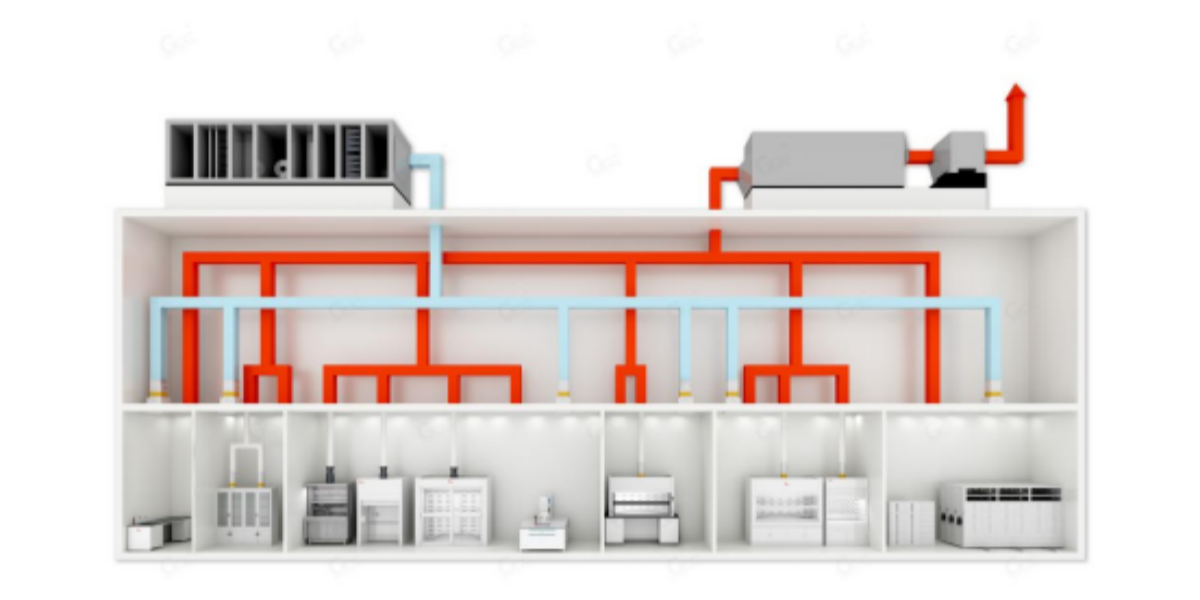

3. Integration of Local Exhaust and Terminal Treatment

In laboratory construction, local exhaust systems must work in coordination with terminal treatment solutions. Local exhaust devices remove contaminants at the source, while terminal systems purify gases before releasing them into the atmosphere.

3.1 Local Exhaust Design

Install local exhaust devices at workbenches and fume hoods where hazardous gases are generated. By optimizing airflow and using high-efficiency exhaust systems, these devices protect personnel from exposure.

3.2 Terminal Treatment Solutions

At the end of the exhaust line, gases require thorough purification. Terminal treatment technologies include:

- High-Efficiency Activated Carbon Units: Adsorb organic gases like formaldehyde, xylene, and alcohol.

- UV Photolysis Systems: Decompose VOCs and solvent vapors.

- Chemical Treatment Towers: Neutralize highly toxic or corrosive gases to meet environmental standards.

4. Coordination Between Ventilation and Exhaust Systems

Ventilation and exhaust gas treatment systems must operate in harmony. Ventilation systems transport pollutants away from work areas, while exhaust treatment systems purify and neutralize gases before release.

4.1 Integrated Design

Connecting the ventilation system outlet to the exhaust treatment system ensures proper airflow and maximizes pollutant removal.

4.2 Energy Efficiency and Environmental Compliance

Optimizing equipment selection and system configuration improves efficiency and reduces operational costs, while ensuring compliance with environmental regulations.

5. Conclusion

Pathology laboratory ventilation and exhaust gas treatment systems are essential for laboratory safety, environmental cleanliness, and personnel protection. By designing and implementing scientifically optimized systems, laboratories can achieve high efficiency, operational safety, and compliance with regulatory standards.

When constructing pathology laboratories, engineers must consider ventilation, exhaust treatment, and airflow together to create a healthy and compliant working environment.

If you have any questions or needs regarding pathology laboratory ventilation and exhaust gas treatment, contact Guangzhou Cleanroom Construction Co., Ltd.. We provide professional design and tailored solutions for safe, efficient, and environmentally compliant laboratories.

坤灵最新logo-scaled-1.png)